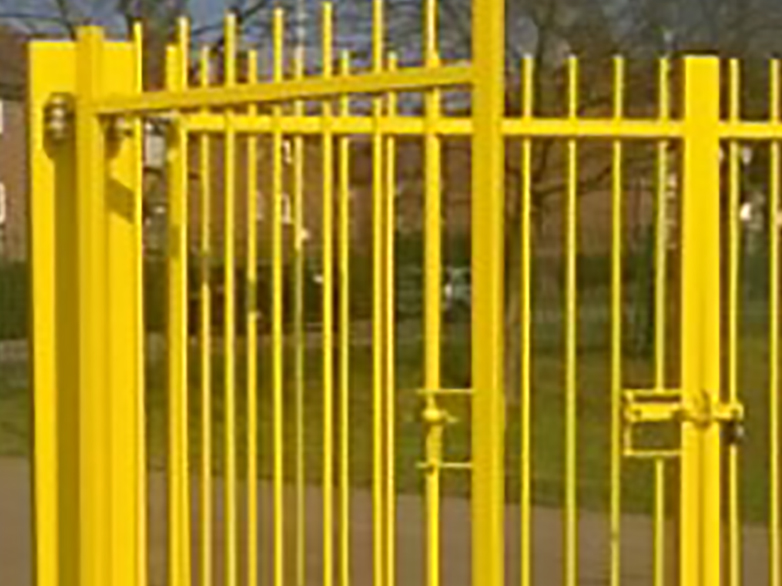

This heavy-duty gate needed to be hung in the opposite direction to allow it to be securely locked open when in use - a crucial feature to ensure on-site safety. Due to the gate's weight and usage, any structural modifications required professional attention to meet both safety and compliance standards.

Our experienced fabrication team, which includes fully coded welders, carried out the repositioning using secure welding techniques. On completion, we issued the client with full documentation to certify the welding work, offering peace of mind and a high-quality finish that meets industry regulations.

Repositioned for Safety

Expertly Hung to Lock Open

For this project, the gate needed to swing in the opposite direction to allow it to be locked safely in place when open. This not only improved day-to-day site safety but ensured the gate wouldn't pose a hazard during busy operations.

- Gate repositioned for improved site safety

- Custom hinge work to support reversed swing

- Secure locking solution when gate is open

- Tailored for operational flow on-site

- Minimal disruption during fabrication and install

Coded Welding & Certification

Structural Confidence Built In

Structural integrity was essential for this heavy gate. Our coded welders used precise techniques to deliver a safe and compliant finish. The client was issued with documentation certifying the work for added assurance.

- Welding by qualified, coded professionals

- Certification issued upon completion

- Strong, clean welds for long-term performance

- Meets safety and structural regulations

- Delivered with professionalism and care